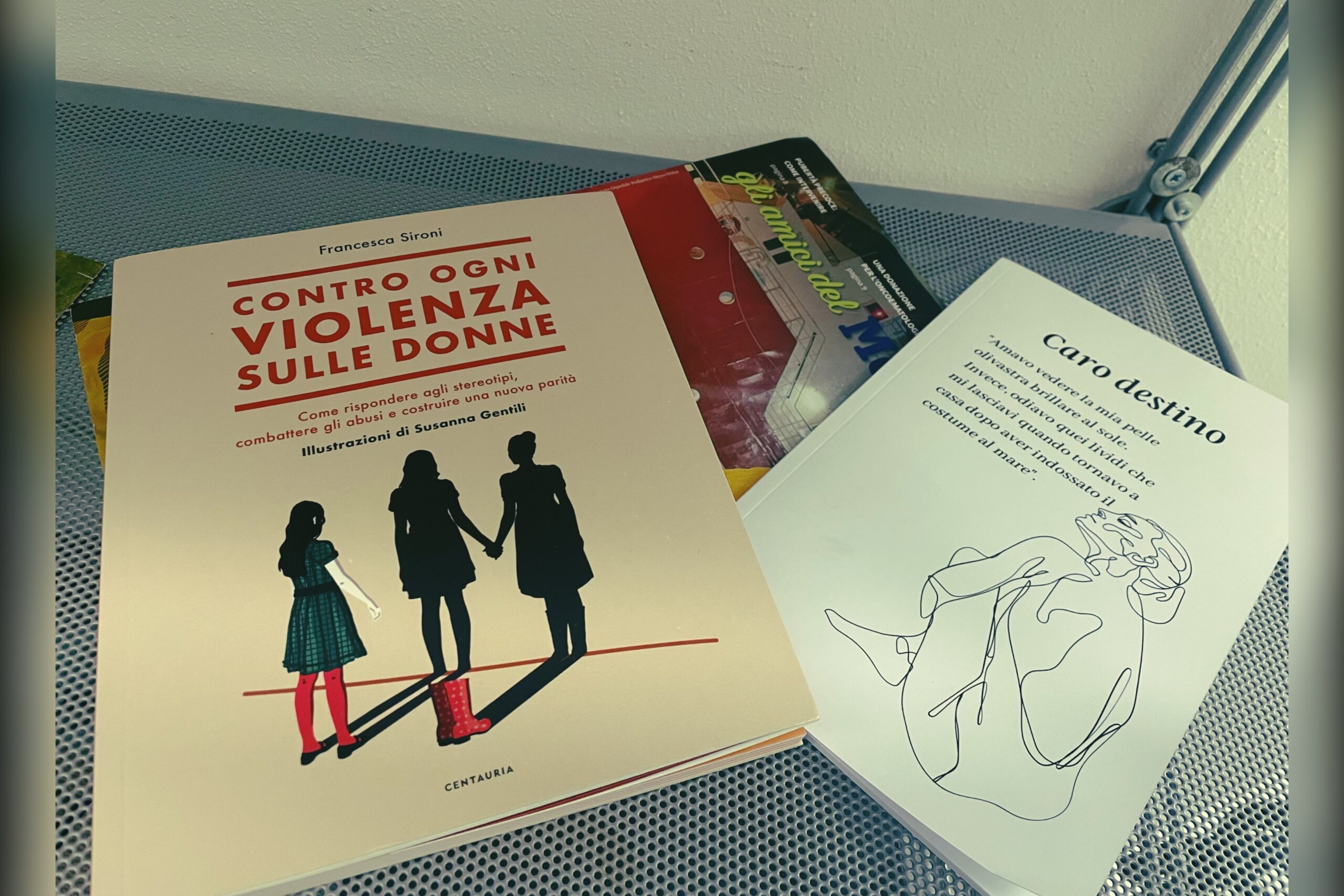

In the month against violence against women and in a period in which feminicides are too often talked about in the news, Steel Project Engineering has undertaken a small project to raise awareness on the issues of gender equality and combating violence against women. We have in fact purchased some books dedicated to these topics and made them available to our collaborators.

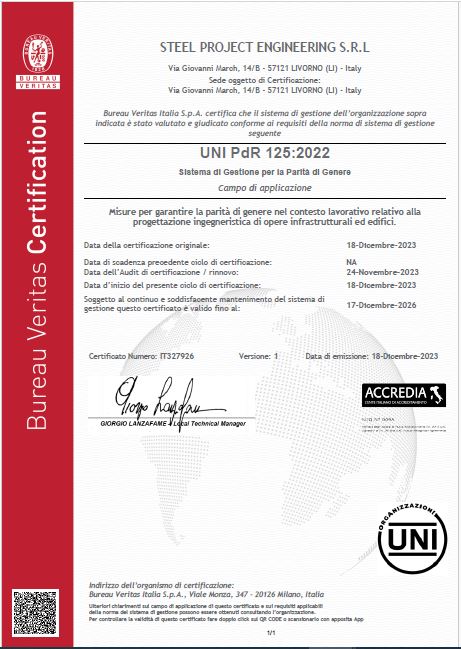

Our commitment on this front has led us to undertake the certification process for compliance with the PdR125:2022 Practice for Gender Equality and we hope that awareness on these issues will spread more and more.

On our website we have set up a contact form in which it is possible to send messages in a completely anonymous form (just do not enter your name and email address, but only the subject of the message) for any report related to aspects of Gender Equality.

Our job advertisements are always aimed at men and women without distinction, indeed, we hope to be able to achieve equality in the coming years. We are always looking for graduates in civil engineering, structural branch, and also designers with knowledge of 2D drawing programs (in particular Autocad) and BIM software.

If you have the above-mentioned requirements and are interested in working in a stimulating environment, which knows how to valorise differences and which cultivates aspects linked to parenthood (3 of our collaborators have children under the age of one year, and another collaborator will become a father in 2024), we invite you to send your CV to segreteria@steelproject.it .