Completion of Spillway Bridge Launch

A Bridge Over the Crest of Africa’s Largest Dam: A Complex Structural Engineering Project in an Unprecedented Context

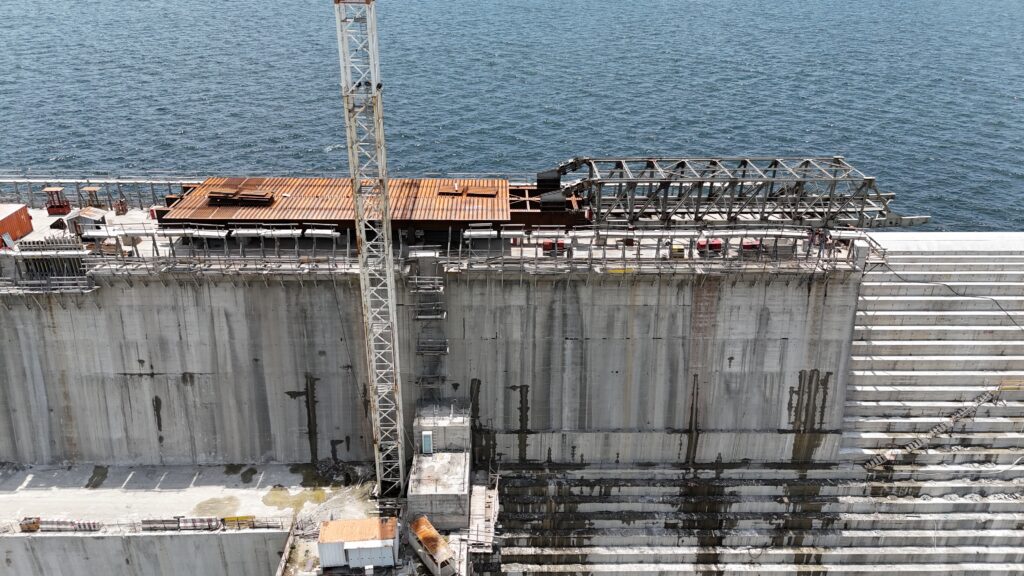

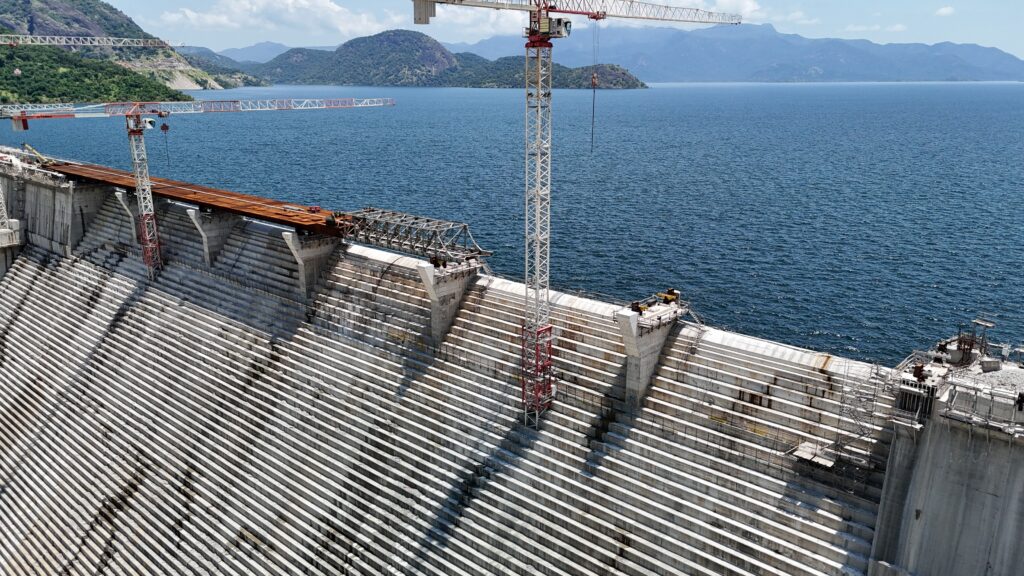

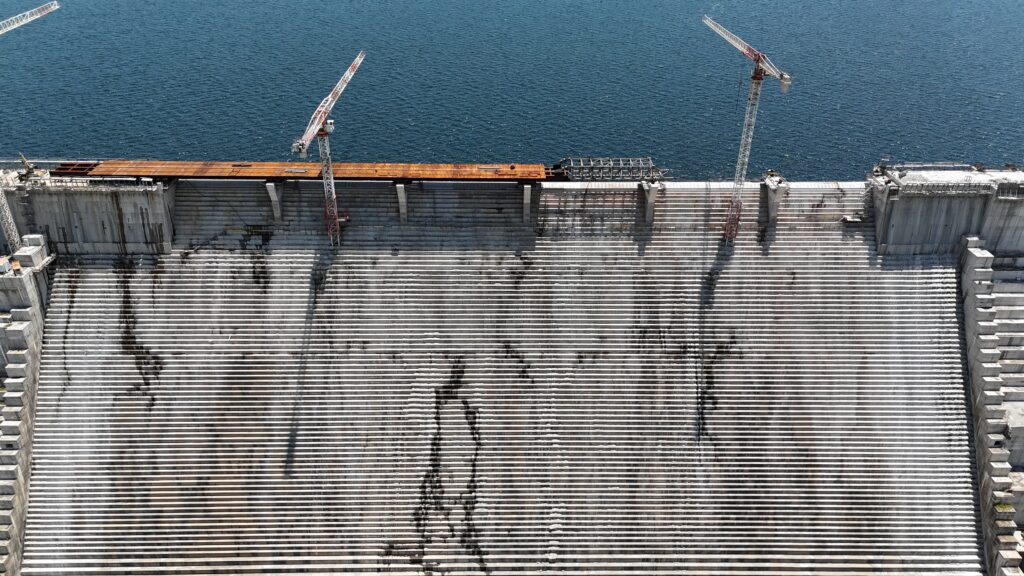

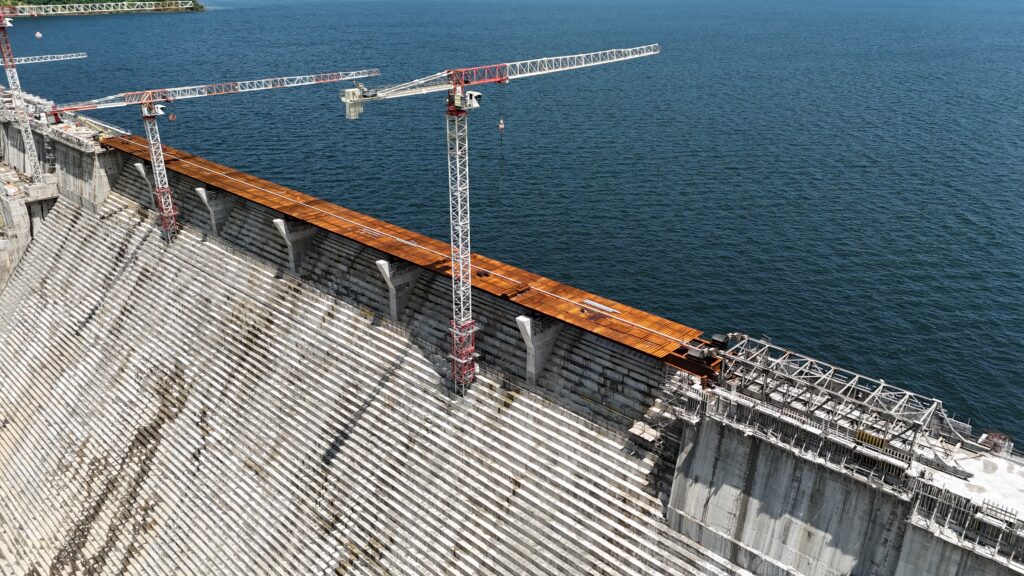

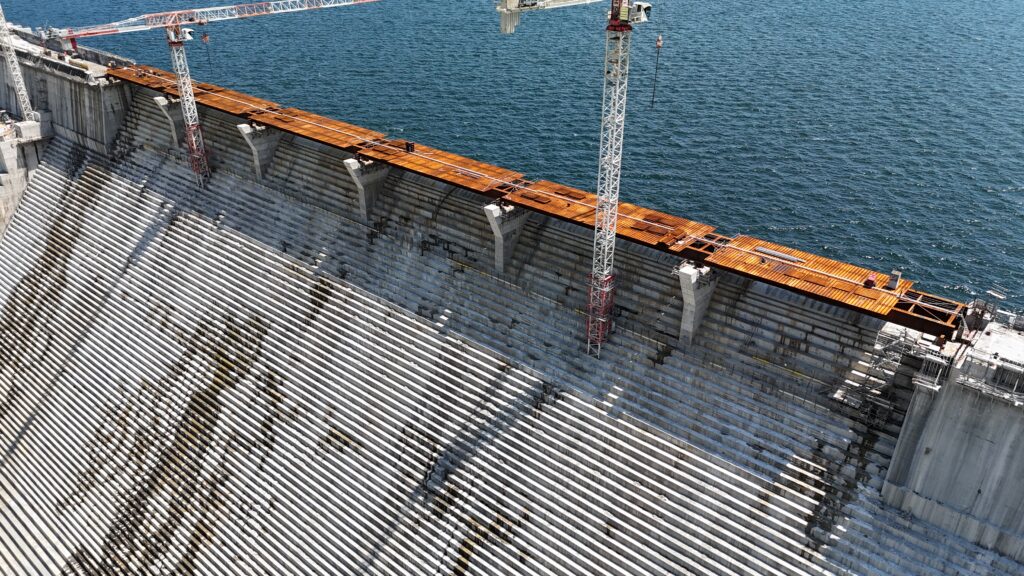

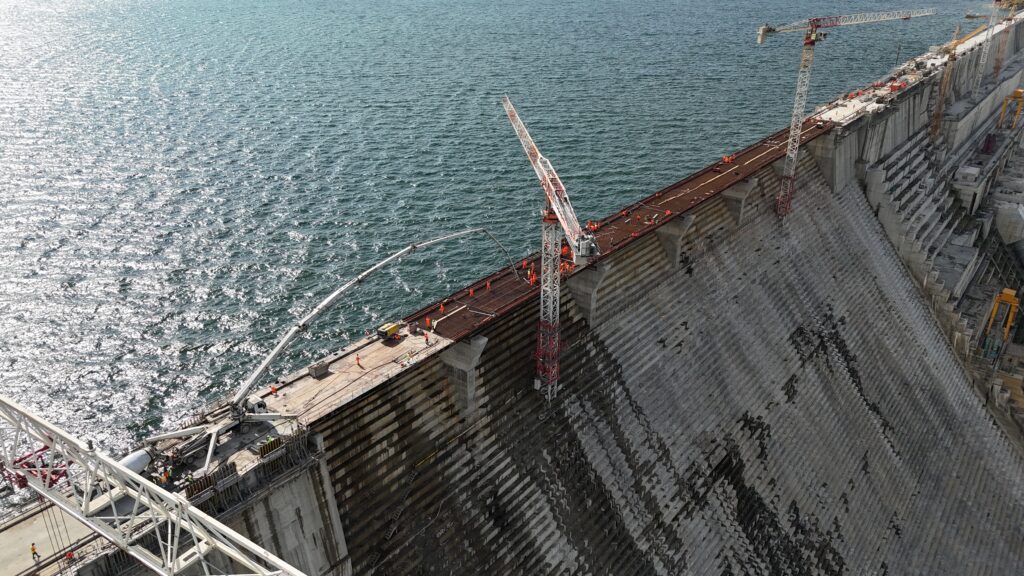

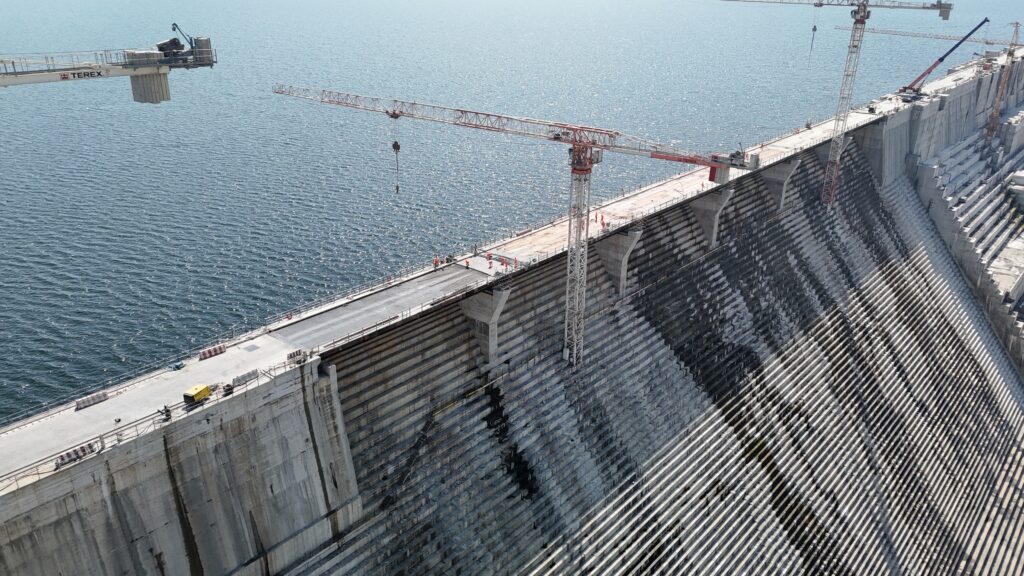

Last October, the assembly and launching of the Spillway Bridge, a road bridge built over the spillway of the Grand Ethiopian Renaissance Dam (G.E.R.D.) in Ethiopia, was completed. The casting of the slabs is currently being finalized, and the static testing of the deck will be carried out shortly. This project stands out for its technical complexity and the unique integration with Africa’s largest dam, a strategic infrastructure for the region’s energy future.

Technical Characteristics of the Bridge

- Structural Type: A road bridge with three beams made with a composite steel-concrete solution, spanning six longitudinal spans, and a platform width of about 11.6 meters.

- Spans: 32 m + 38 m x 4 + 32 m – Total Length: Approximately 216 meters.

- Location: The road deck on the dam crest is located above the spillway, a strategic area for water flow regulation, supported by two abutments and five reinforced concrete piers built atop the spillway.

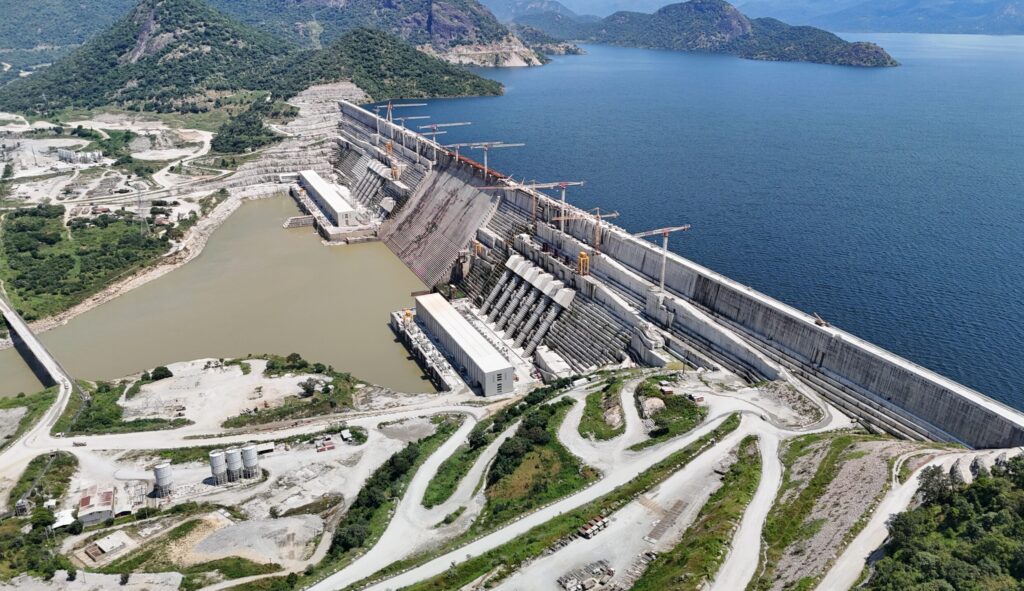

The Grand Ethiopian Renaissance Dam (GERD)

The dam, located on the Blue Nile, is a monumental project set to redefine the energy landscape of East Africa. Key facts about this energy infrastructure include:

- Height: Approximately 150 meters from the existing ground level.

- Crest Length: 1.8 km for the RCC dam, approximately 5.0 km for the sand dam.

- Reservoir Volume: 74 billion cubic meters.

- Installed Capacity: Over 6,000 MW, enough to meet the energy needs of millions of families and promote energy export to neighboring countries.

Challenges of the Bridge Project

The construction of the Spillway Bridge required a high-level engineering approach to address unique challenges:

- Integration with the Dam: The bridge was designed to integrate harmoniously with the dam structure, handle the design seismic accelerations expected at the dam crest, and ensure the spillway’s operation at maximum hydraulic flow.

- Advanced Design: The specific context of the bridge required advanced engineering solutions to ensure the bridge’s resistance to operational loads and site environmental conditions.

- Assembly Techniques: The assembly and launching of the deck were carried out with great precision, using cutting-edge methodologies to meet the project’s timelines and technical constraints.

This project is the result of a multidisciplinary collaboration involving highly qualified engineers, technicians, and professionals, whose combined efforts have transformed a complex design into a unique work in terms of context and execution time.

Steel Project Engineering handled the structural Executive Project of the deck, assembly and launching checks, and the Executive Project of the launching and lowering equipment.

We thank WeBuild S.p.A., General Contractor of the work, for the trust placed and for kindly providing the photographic material.

Steel Structure Manufacturer: MBM S.p.A.