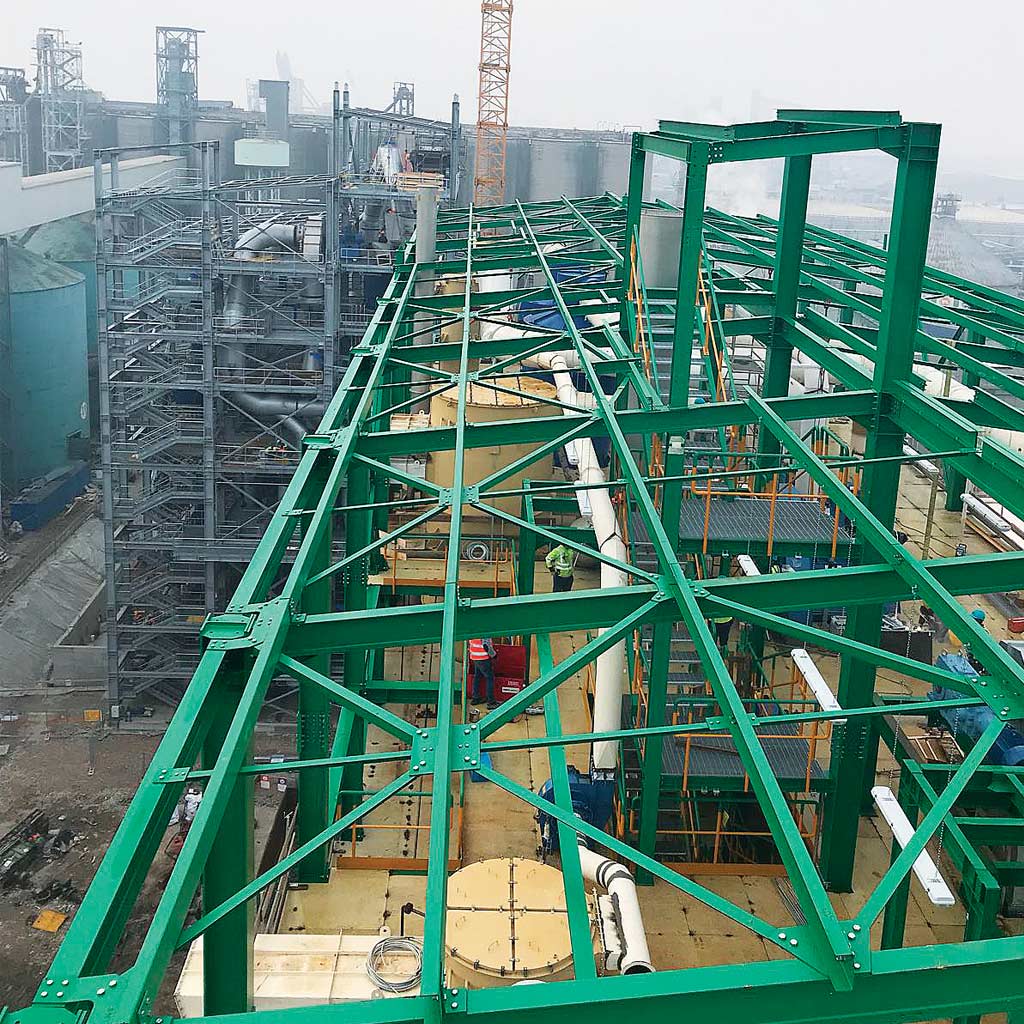

Connection design of the steel structures.

Category: Industrial Buildings

Services: Final detailed design

Period: November 2018 – January 2019

Client: Cimolai S.p.a.

Design of the connections of a spatial steel structure with mixed truss-frame behavior.

Validation of the final design and optimization of the connections considering the six internal actions by means of 3D analysis.

Design of the connections of a spatial steel structure with mixed truss-frame behavior.

Validation of the final design and optimization of the connections considering the six internal actions by means of 3D analysis.