Reinforcement intervention on the Gerber saddles of the existing RC bridge.

Category: Revamping of existing structures

Activity: Final Design

Period: October 2020 – ongoing

Client: Setin s.r.l.

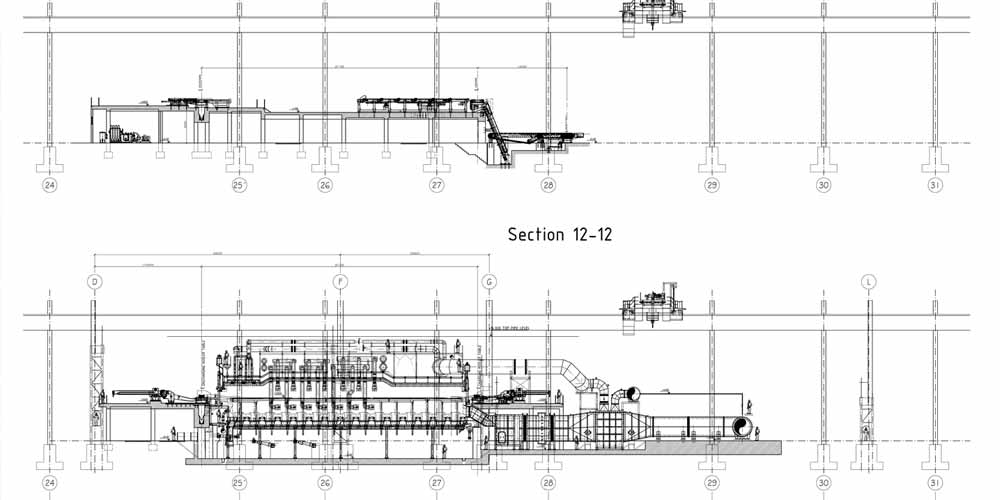

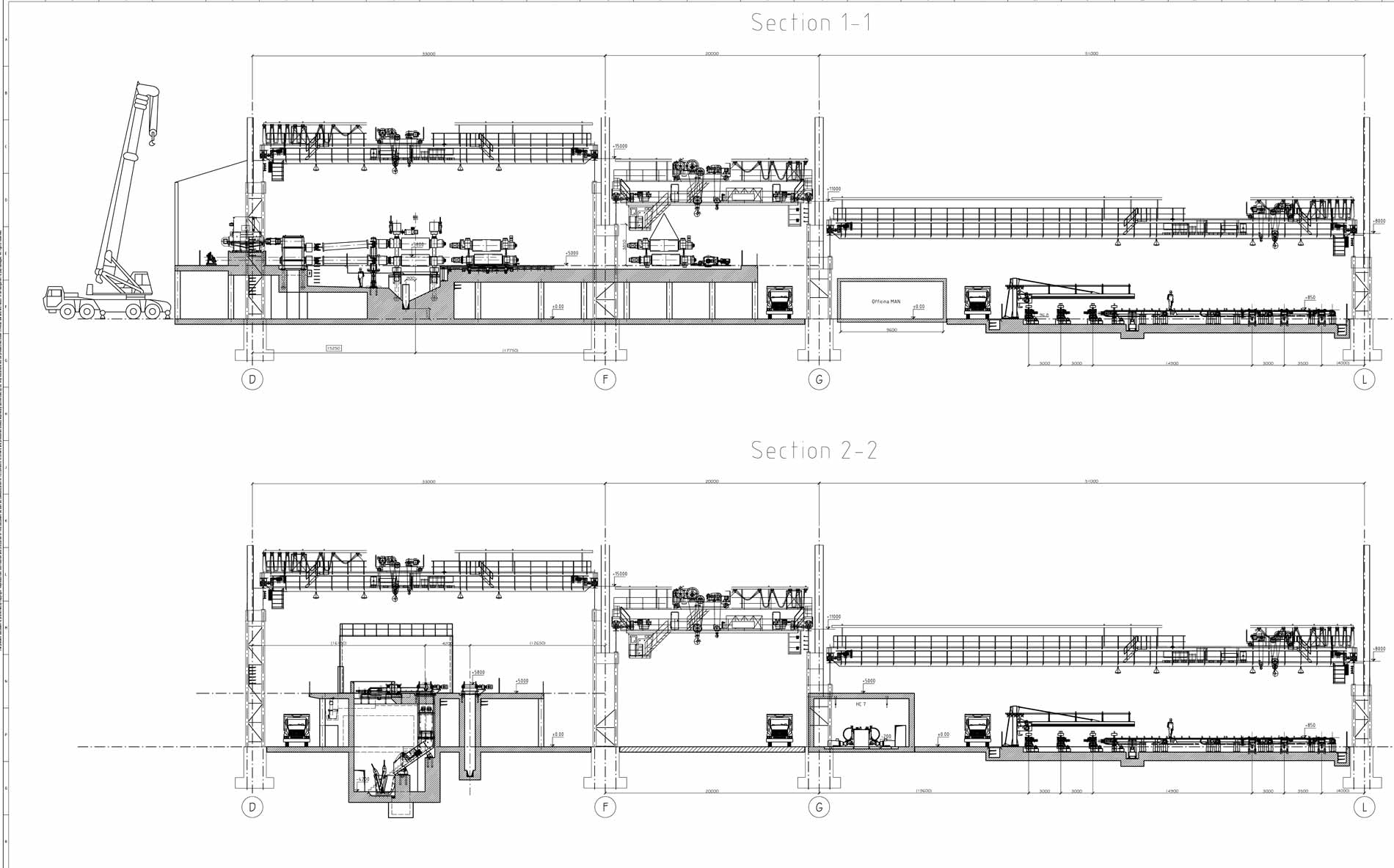

The bridge is an existing three-span reinforced concrete bridge with a total length of 103.10 m. The static diagram is isostatic: the central span is in fact interrupted by two Gerber saddles, 21.50 m apart. The parts of the beam overlapping the piles are made with a three-cell box, while the remaining parts have an open section with four webs connected to the slab.

The bridge is an existing three-span reinforced concrete bridge with a total length of 103.10 m. The static diagram is isostatic: the central span is in fact interrupted by two Gerber saddles, 21.50 m apart. The parts of the beam overlapping the piles are made with a three-cell box, while the remaining parts have an open section with four webs connected to the slab.

The intervention to be carried out consists in positioning a metal beam under each web of the box and the open part. Each metal beam has the function, in the event of the Gerber saddle collapsing, of supporting the central span by levering on a pair of bars suspended from the web of the box section, which also serves as a point of support for the lever itself.

The intervention to be carried out consists in positioning a metal beam under each web of the box and the open part. Each metal beam has the function, in the event of the Gerber saddle collapsing, of supporting the central span by levering on a pair of bars suspended from the web of the box section, which also serves as a point of support for the lever itself.